HUATAO LOVER LTD

- Annual Revenue 50000000-80000000 USD

- Employees 50~100

- Year Established 2001

- Manufacturer, Exporter, Trading Company

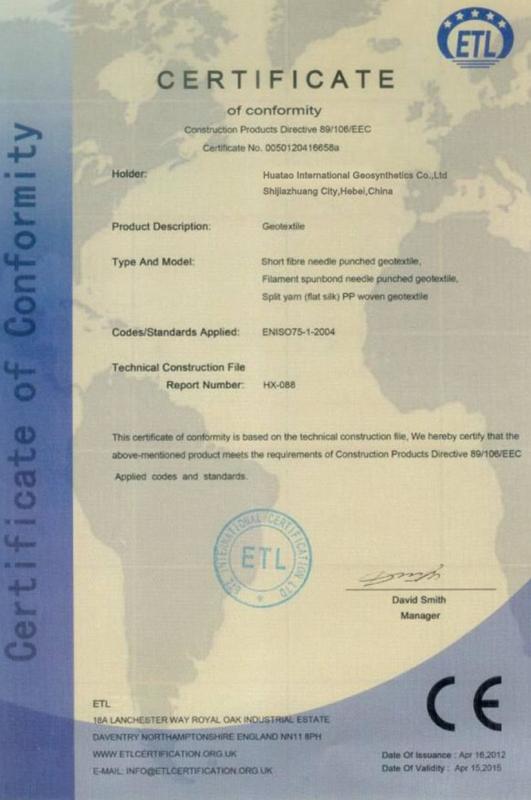

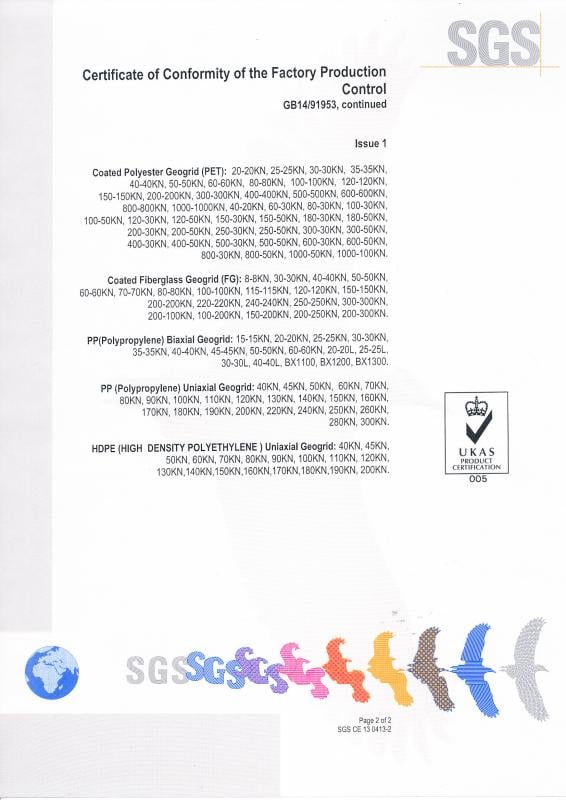

Certification

See All

Copyright 2023 ucbis.com All Rights Reserved.

Copyright 2023 ucbis.com All Rights Reserved.

High Speed 13-30gsm Tissue Paper Maker Machine

High speed toilet tissue paper making machine, sanitary napkin pape rmachine

About us

We are a professional manufacturer of high cost - performance equipments related to pulping equipment , papermaking equipments , complete sets of paper machine production line , old paper machine production line rebuilt , spare parts of paper machine , etc . Besides , our company owns excellent term with professional engineers and sales , we can offer the best proposal with the customer requirements .

The process flowing chart:

Raw materials -pulper--vibrating sieve--pulp tank--pulp pump--bleach machine(thruster)--refiner machine--pulp tank--pulp pump--pressure sieve--pulp tank-- pulp pump--except sand machine--net box--cylinder--blanket--paper making machine--drying--roll paper--the big finished jumbo paper -- process machine.

Main structure

1. cylinder part: 1500mm×2250mm stainless steel wire mould(1pc), Cylinder mould pressure forming machine (1 set),450mm×2250mm couch roll(1 pc),rubber HSD38°±2

2. Dryer part: 2500mm×2250mm Dryer ( 1 pc ), 500mm×2250mm carrier roller( 1 pc ), 300mm×2250mm wringing roll(2 pcs),including all the felt carrying rolls,air-powered pressure device,rubber HSD 90°±2, equiped with double-layer exhaust bood on the dryer.

3.Winding part:1000mm×2250mm sweat cylinder (1pc),280mm×2250mm fly rubber roll( 1pc ).rubber HSD75°±2. winding on the sweat cylinder. Equipped with the 250 speed reducer(1 set)

4. Rewinding and cutting part: matching 1880mm rewinding and perforating machine,toilet roll cutting machine..

5. Drive and control part: adopting AC frequency conversion speed, drive step by step.

Main Technical Parameter of paper making machine

|

Raw material: |

recycled paper,wood pulpboard |

|

Output paper: |

High & medium grade of toilet paper,tissue paper |

|

Output weight: |

13-30g/m2 |

|

Net width: |

1880mm |

|

Wire width: |

2250mm |

|

Capacity: |

5-6T/D |

|

Rail guage: |

3000mm |

|

Speed : |

150m/min |

|

Design type: |

Box type,Back - stirring type |

|

Design Standards: |

CNS Export equipment |

Company Profile

We have passed CE, SGS, ISO quality system certification and all manufacture processes are conducted by the standard strictly.

Our company undertakes design, manufacturing, supply, erection and commissioning of paper machines & new pulp mill and modernization of existing pulp mill and paper machines on a turnkey basic. We also have innovative research team,always follow the

advanced technology of Finland,Denmark and Italy,Gemany;

Skilled and careful installation team.

Trade market:

Our machines sell good in more than 30 countries,such as Nigeria, Egypt,

Uzibekistan,Pakistan,America,Uganda,Turkey,Brazil,Fiji,Paraguay,Ethiopia,etc. High quality and perfect service have reserved customer's praise and more orders. We have established good relationship with many foreign countries because of our good quality and perfect service.

Our Services

1. Reasonable suggestions for selection of equipment.

2. Provide detailed description and assembly drawing , to make you more aware of the device's ability to work.

3. Engineers on-site equipment installation and commissioning.

4. Train and teach your worker to operate the paper machine,

5. Professional technical guidance and technical support during your production, make sure the device's work properly and production.

6. Equipment modification and updating.

7. We will testing installation machine in the factory workshop , to ensure safety and quality.

8. Supply Carbonless paper and Paper coating chemicals ,formulation ,technology and other suggestion to customers.

9. After-sales service for one year: equipment maintenance guidance.

10. Provide Turnkey projects.

Visit Website