GUANGDONG HWASHI TECHNOLOGY INC.

- Annual Revenue 6000000-8000000 USD

- Employees 150~200

- Year Established 2001

- Manufacturer, Importer, Exporter, Trading Company, Seller

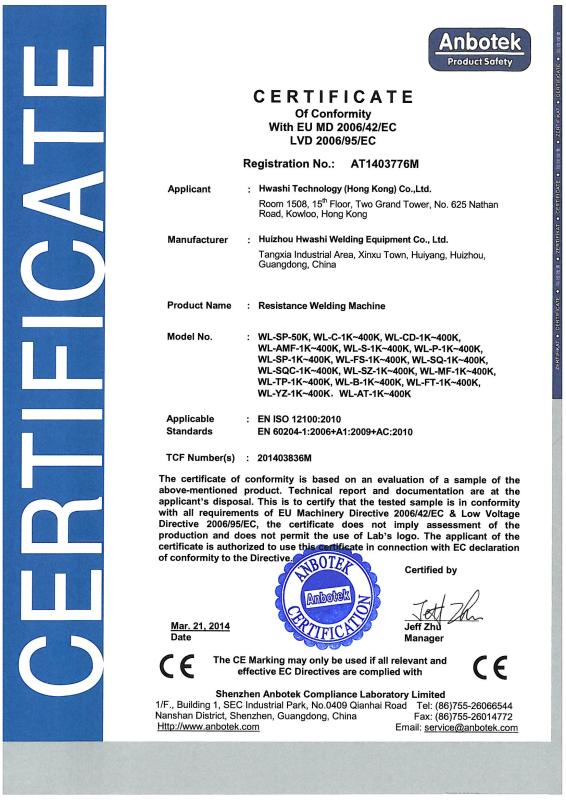

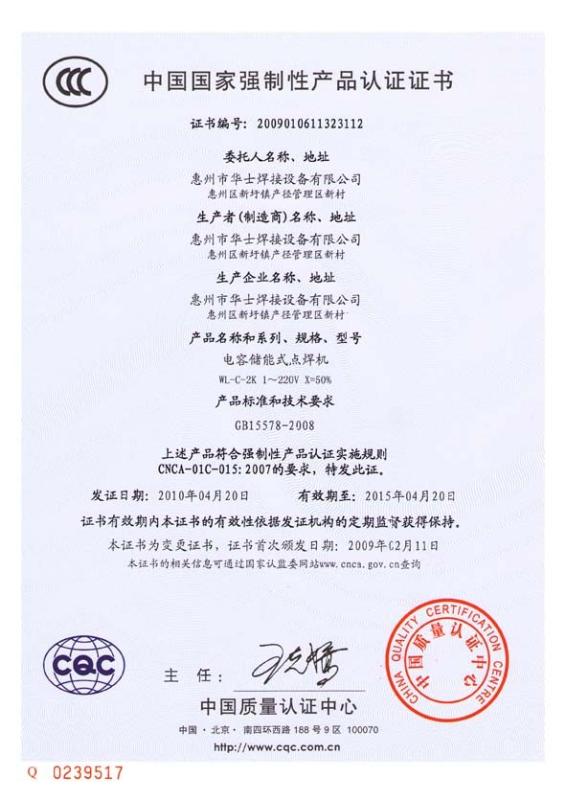

Certification

See All

Copyright 2023 ucbis.com All Rights Reserved.

Copyright 2023 ucbis.com All Rights Reserved.

Double-Heat Capacitor Discharge Spot Welding Machine for Welding Heating Tube

Double-Heat Capacitor Dischargespot Welding Machine for Welding Heating Tube

COMPETITIVE ADVANTAGE

1. HWASHI is the leading brand in resistance welding industry in China for 20 years; Factory direct sale, competitive price.

2. Customized Service: We can help to design and develop the welding machine according to your requirement. We are flexible and capable Supplier.

3. Genuine Product with Excellent Quality: 12 months warranty. Our machines are strictly complied with ISO9001:2000 and China Compulsory Certification. Most of our machines enjoy 8-10 years service life. 100% guarantee test before delivery.

4. After Sales Service and Technical Assistance: 24 hours technical support by email. Our professional team is always here willing to be your technical consultant.

5. Quick Delivery: Our company provides just-in-time delivery.

6. Prompt Response to Customers: Your satisfaction is the goal we pursue.

DESCRIPTION

1. This machine is suitable for two terminals of heating tube with dual design of electrode

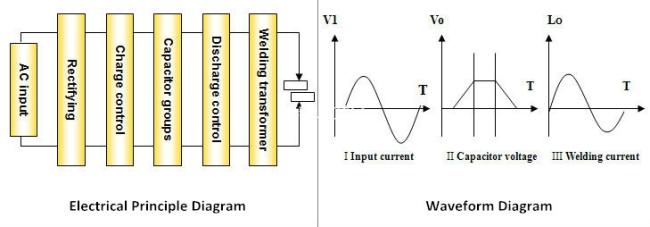

2. The machine is designed to use Japanese "NIPPON CHEMI CON"(NCC225UF/475V) to store and release. electricity . The following picture is the working principle of Capacitor Discharge Welding Machine

SPECIFICATION

| Model | Voltage | Power | Output Heat | Capacitance | Pressurization |

Electrode Stroke |

Closure |

Platform Distance |

Electrode Distance |

Cooling Water |

| V | KVA | J | μF | kg | mm | mm | mm | mm | Lit/min | |

| WL-CD-3K | 220/1Φ | 3.5 | 1500 | 13500 | 350 | 80 | 145-225 | 250 | 320-420 | Min.2 |

| 380/1Φ |

MATERIAL CONFIGURATION

| S.N. | Name | Specification | Brand | Origin |

| 1 | Charging silicon controlled | KP-150 | MCC | U.S.A |

| 2 | Discharging silicon controlled | SKKT1000-12E | MCC | U.S.A |

| 3 | Rectifier diode | ZP-150A | MCC | U.S.A |

| 4 | Current-limiting resistance | 100W/100Ω | NANFA | Hong Kong |

| 5 | Capacitance | 225UF/475V | Nitponchemi.con | Japan |

| 6 | Discharging contactor | JMC-75 | LG | South Korea |

| 7 | Charging contactor | JMC-18 | LG | South Korea |

| 8 | Charging control panel | WD-20DC-1 | HWASHI | Home-made |

| 9 | Discharging control panel | WD-20DC-2 | HWASHI | Home-made |

| 10 | Charging switch | 15A | MITSUBISHI | Japan |

| 11 | Tail switch | DS-231 | IDEC | Japan |

| 12 | The main magnetic valve | 3000# | SANWO | Korea |

| 13 | Pressing magnetic valve | 4# | SANWO | Korea |

| 14 | Air group | 4000# | SANWO | Korea |

Visit Website