Shenzhen Senyan Circuit Co., Ltd.

- Annual Revenue >1000000 USD

- Employees >100

- Year Established 2017

- Manufacturer, Distributor/Wholesaler, Exporter, Other

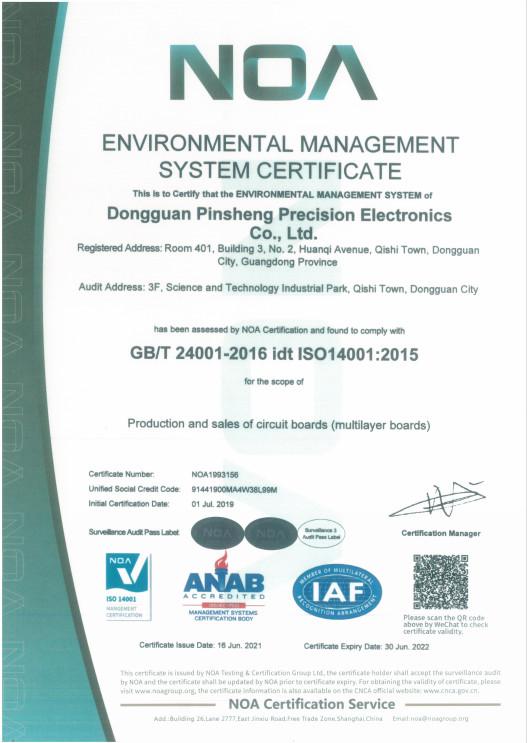

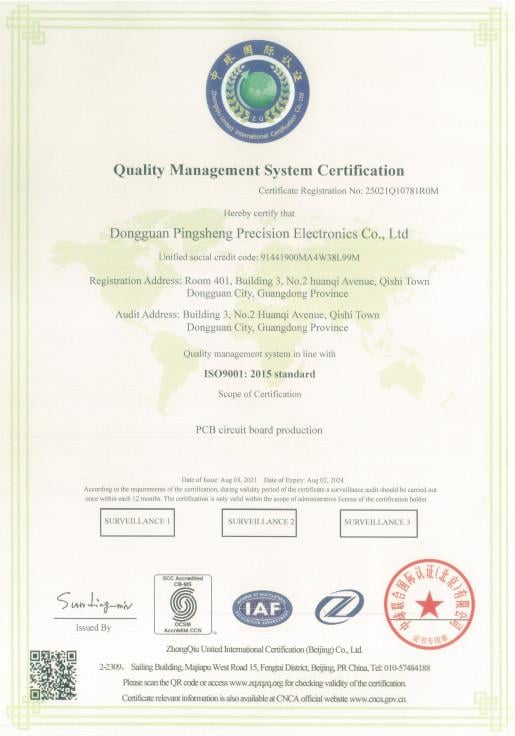

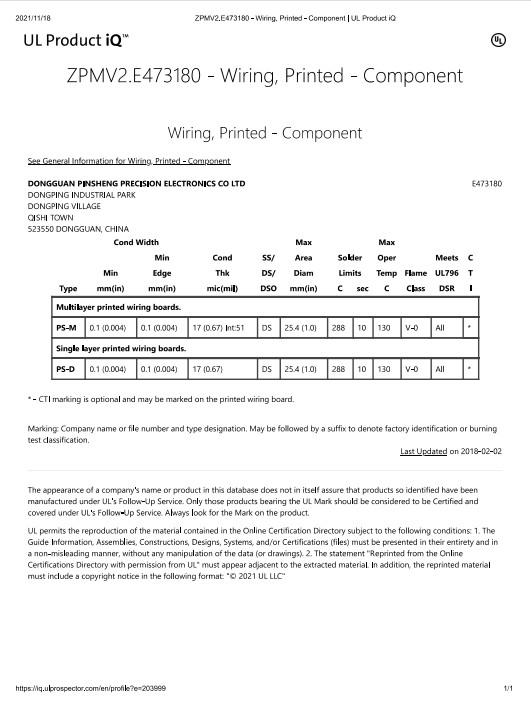

Certification

See All

Copyright 2023 ucbis.com All Rights Reserved.

Copyright 2023 ucbis.com All Rights Reserved.

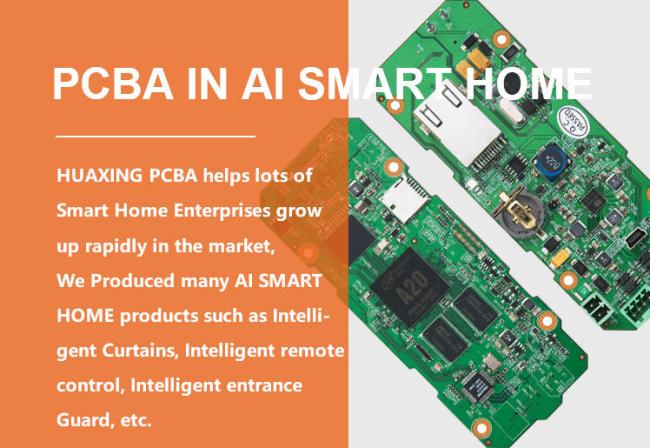

2 To 18 Layers 94v0 Flexible PCB

Pcba Manufactures Customized Qi Wireless Charger PCBA Specialized Component Purchasing Assembly Manufacturer

Welcome To Senyan.

Senyan is a PCB manufacturer, Senyan‘s capable of providing turn-key and partial turn-key printed circuit board assembly services.

For full turn-key, we take care of the entire process, including manufacturing of Printed Circuit Boards, procurement of components (100% original) , PCBA Testing , continuous monitoring of quality and final assembly.

Our main service:

1. PCB development and design;

2. PCB manufacturing from 1 to 32 layers(Rigid PCB,Flexible PCB,Ceramci PCB,Aluminum PCB);

3. PCB Clone;

4. Component sourcing;

5. PCB Assembly;

6. Write program for customers;

7. PCB/ PCBA Test.

We provide one-stop PCB/PCBA customization services. To meet all of customer's PCB/PCBA requirement is Senyan's goal

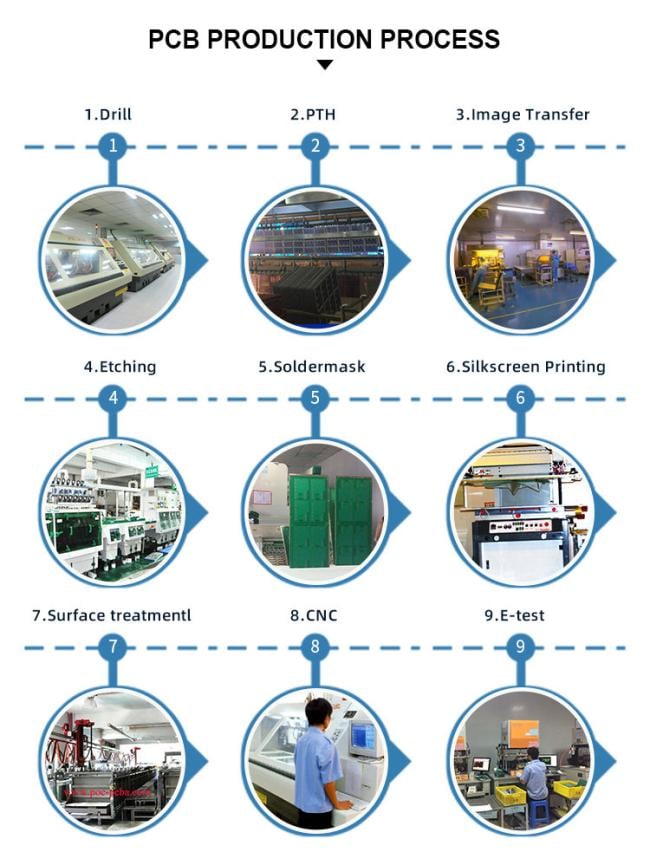

1.To offer good quality PCB/PCBA to our customer, we will do many kind of testing to ensure quality before shipment

2.Outgoing test to check min PTH Cu thickness, Min surface Cu thickness, ENIG Au data,Ni data, Au layer adhesion testing, soldermask adhesion testing, silkscreen adhesion testing, Thermal stress testing, hardness testing, Twist testing, Bow testing

3.Microsection testing to check hole Cu thickness, Surface Copper thickness, Wrap copper thickness, Hole Wall Integrity, soldermask thickness and stack up.

4.E-test to check any open/short circuit.

5.Thermal Stress Test to avoid any Delamination, Measling and others.

6.Solderability of PTH to avoid any discolor, Wrinkles, Blisters, Measling, Blow-Hole, Solermask peel off, and soldermask filled in hole-wall incompletely.

Impedance testing, and so on……

Please feel free to contact with us!

|

Your Troubles

|

|

Our Strategy

|

||

|

Lack of engineering experience

Various unexpected problems, causing the project to fail

|

|

Rich engineering experience: Bom Engineer/ Product Engineer/ Technical Engineer /Purchasing Engineer.Eliminate Problems and pitfalls at the design stage

|

||

|

Coordinating multiple suppliers

Insufficient time and energy

|

|

PCB Assembly and welding factory, Component procurement team,Function Test , Finished Product Assembly. Provide one-stop service, save time and worry

|

||

|

Product quality control

High hardware trial and error cost

|

|

Rigorous process and strong strength

We have established a standardized and rigorous process and system to effectively reduce quality problems

|

||

|

Traders do not have physical factories

The quality is not guaranteed, Documents easy to disclose

|

|

Own teams and factory, the delivery time is more controllable

|

||

|

Hard delivery guarantee

The market can't wait

|

|

Complete Organizational Structure: Project Department, Engineering Department, Purchasing Department, Quality Department,

Production Department, Etc. |

||

Why Choose Us

One stop service:one stop contract manufacturing service.

Quality control:strict quality control with100%AOI ,X-ray inspection.

Price:competitive price in peer industry.

Experience:over 10 years experienced engineering team.

Sales net:sales network covers over 200 counties and regions.

Senyan is a professional double sided PCB manufacturer.we produce varieties of 4layers sided PCB that include FR4 base material, polyimide base material,Metal base material, copper base material.products are sold to America,Uk,Germany,France,Italy,Belgium,Japan, Russian,Spanish,India,Hungary,Brazil and Korea etc.

Technical Requirement for pcb assembly:

1) Professional Surface-mounting and Through-hole soldering Technology

2) Various sizes like 1206,0805,0603 components SMT technology

3) ICT(In Circuit Test),FCT(Functional Circuit Test) technology.

4) PCB Assembly With CE,FCC,Rohs Approval

5) Nitrogen gas reflow soldering technology for SMT.

6) High Standard SMT&Solder Assembly Line

7) High density interconnected board placement technology capacity.

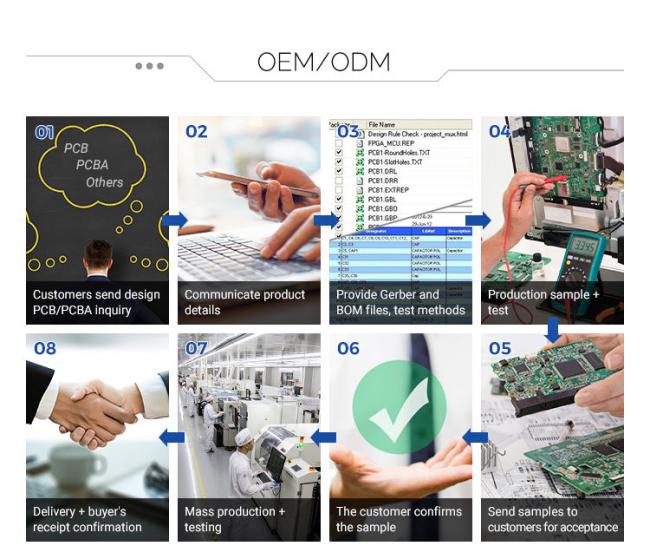

Production Requirement for pcb assembly:

1.Gerber Files (Eagle and PCB File are available).

2.BOM list.

3.Clear pictures of PCBA or PCBA samples to us.

4.Pick N Place file.

5.Test procedure for PCBA.

|

SMT Manufacturing Capability

|

|||

|

Item

|

Manufacturing Capability in process | Manufacturing Method | |

| Production size(Min/Max) | 50×50mm / 500×500mm |

|

|

| Production board thickness | 0.2 ~ 4mm | ||

|

Printing solder paste

|

Support method | Magnetism fixture, vacuo platform | |

|

|

Sticking up by vacuo, clamping on both sides ,flexible clamping with sheet, flexible clamping with thick board | ||

| Cleaning Method of printing solder paste | Dry method+ wetting method+ Vacuo method | ||

| Accuracy of printing | ±0.025mm | ||

| SPI | Repeated accuracy of volume | <1% at 3σ | |

|

Mounting component

|

Components size | 0603(Option) L75mm Connector | |

| Pitch | 0.15mm | ||

| Repeated accuracy | ±0.01mm | ||

|

AOI

|

FOV size | 61×45mm | |

| Test speed | 9150mm²/Sec | ||

| 3D X-ray | Shootingangle | 0-45 | |

Detail For PCB:

| Item | Capability |

| 1.Base Material | FR-4 / High TG FR-4 /Aluminum /CEM-1/Rogers/Arlon/Taconic/Teflon |

| 2.Layers | 1-22 |

| 3.Finised inner/outer copper thickness | 1-6OZ |

| 4.Finished board thickness | 0.2-7.0mm |

| 5.Min hole size | Mechanical hole: 0.15mm Laser hole: 0.1mm |

| 6.Controlled Impedance | +/-5% |

| 7.Plugging vias capability | 0.2-0.8mm |

| 8.Outline profile | Rout/ V-cut/ Bridge/ Stamp hole |

| 9.Surface treatment | HASL, HASL lead free, Immersion Gold, Immersion Tin, Immersion Silver, Hard gold, Flash gold, OSP… |

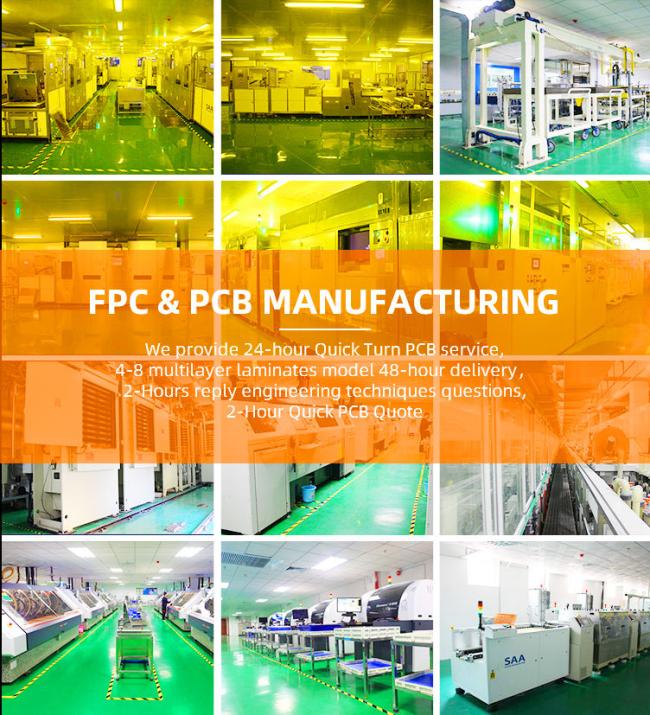

With Large Monthly Production Capacity

With the help of our 15 CAM engineers, 15 SMT machine engineers and 10 BOM analysis engineers, our PCB production capacity can reach 40,000 square meters and EMS assembly capacity at 150 million components per month. Moreover, our reliable world-famous brand component procurements are as follows:

Global procurement database

Distribution partnership

Flexible stocking programs

Integrated customer registered pricing

Extensive global supply chain

OEM sourcing agreements

Q.What service can you supply ?

We are OEM PCB and PCBA manufacturer since 2006,we can provide turnkey solutionincluding RD PCB fabrication,SMT and assembly PCBA inside the enclosure,Functiontesting and other value-added service.

Q.What file you need to prepare if you want to get an quotation from us?

For PCB board, you need to prepare files of Gerber file,it should including RS-274X,ODB++, DXF, PCB, PCBDOC etc formats.

For PCBA(PCB with soldered components), except the file for PCB, you also need to prepare the BOM list (components list), Pick and Place file(txt format), real sample pictureor 3D PDF version file etc.

Q. Do you have any MOQ Limited ?

We havent any limited about MOQ .Sample and mass production all can support.

Q. How to keep our product information and design file secret ?

We are willing to sign a NDA effect by customers side local law and promising tokeep customers data in high confidential level.

Q.How long does it take for PCB and PCBA Quote ?

PCBs quotation within 2 hours can finished the PCBA depend on the components

quantity,if simple, within 6 hours can finished,once complex and more,the 12- 36 hours

can be finished.

*Please note that the following detail will speed up evaluation:

Material:

Board thickness:

Copper thickness:

Surface finish:

Solder mask color:

Silkscreen color:

Q. How about the delivery?

Normally, for sample order, our delivery is about 5 days.For small batch, our delivery is about 7 days.

For mass production batch, our delivery is about 10 days.

But that depends on the real condition when we get your order.

If your order is urgently please contact us directly ,we will priority to deal it and do ourbest to give you satisfied delivery time.

Q.How can we guarantee you receive an good quality product?

For PCB, we will use Flying Probe Test, E-test etc. for it.

For PCBA, we need you to offer us a method or test fixture for the function test.Before that, our inspectors will use microscope and X-ray to check the IC footwelding or bad solder etc.

Q.With payment terms do we accept?

For sample order or small batch, we suggest you to use Pay-pal and Western Union.For mass production batch, we suggest you to use T/T.