Qingdao Shun Cheong Rubber machinery Manufacturing Co., Ltd.

- Annual Revenue 5,000,000-10,000,000 USD

- Employees 20~50

- Year Established 2008

- Manufacturer

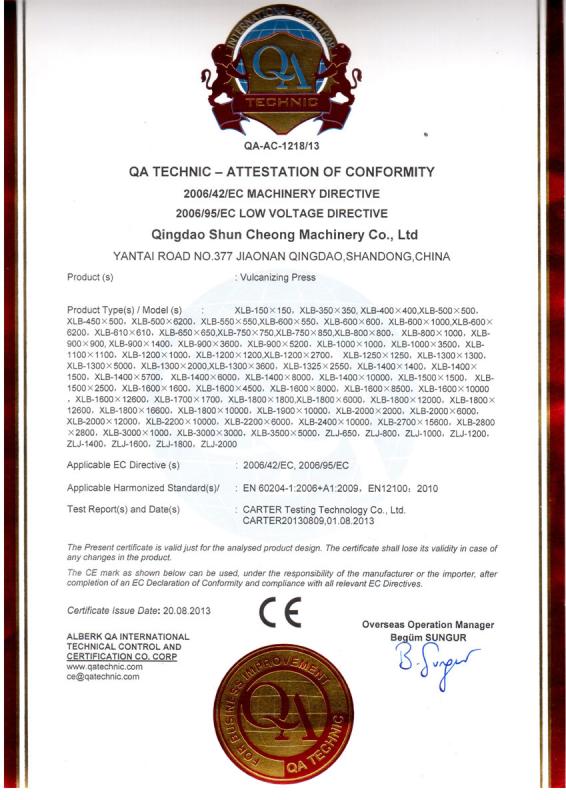

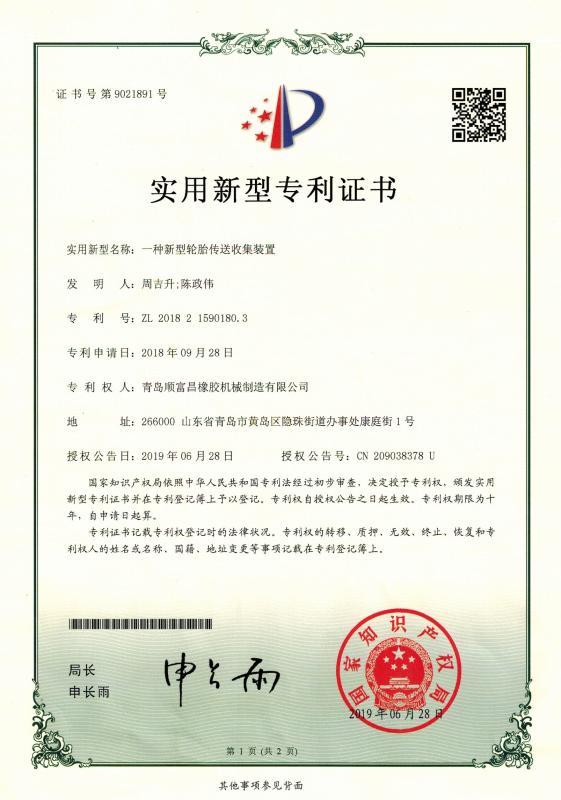

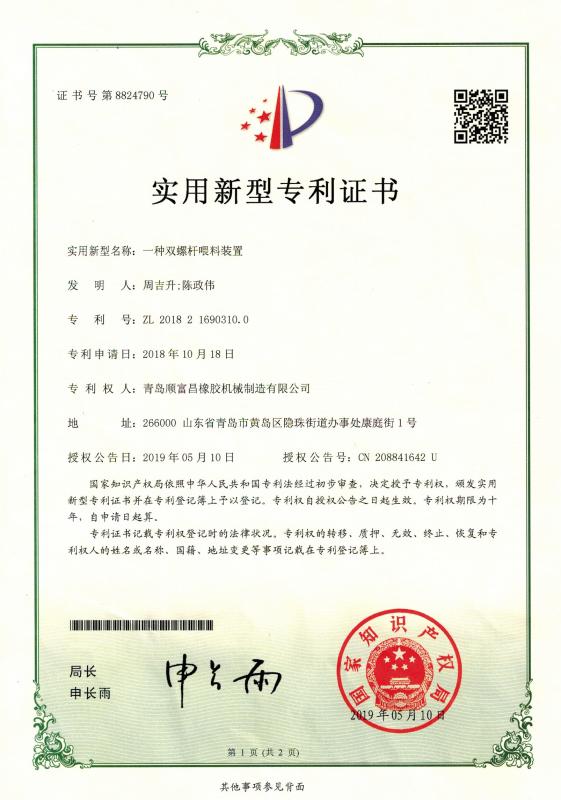

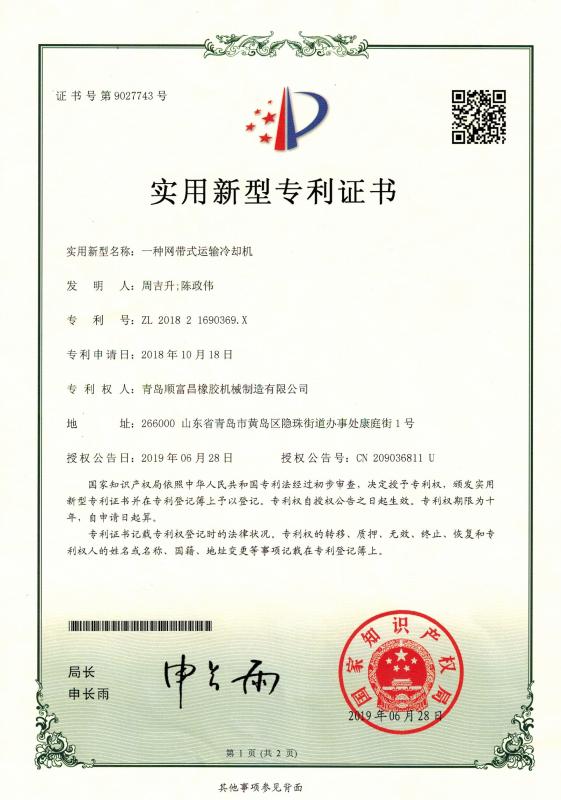

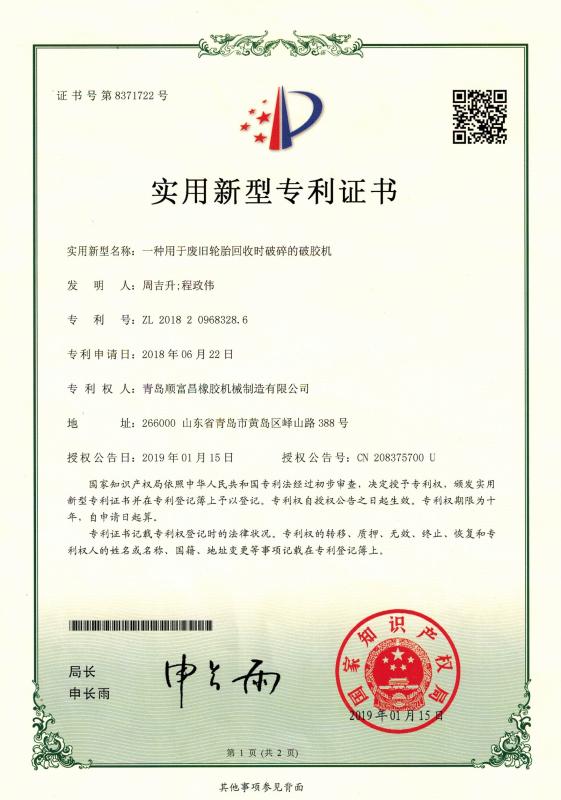

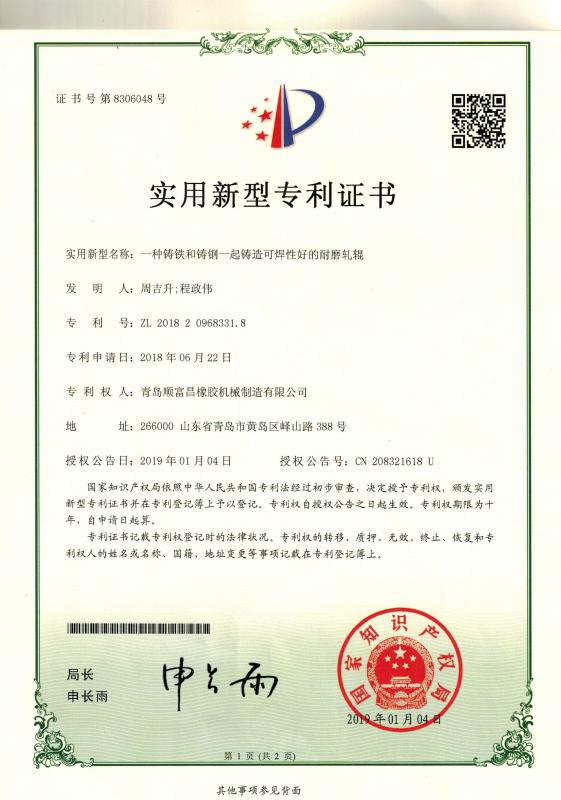

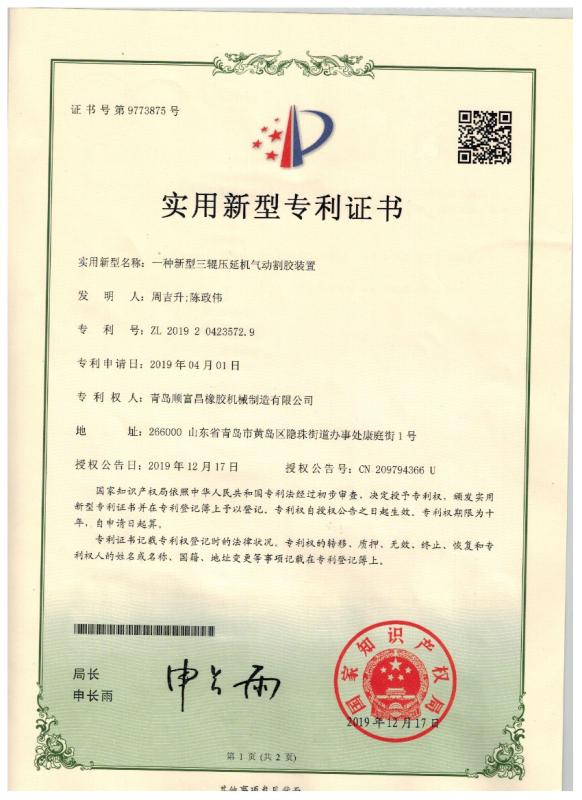

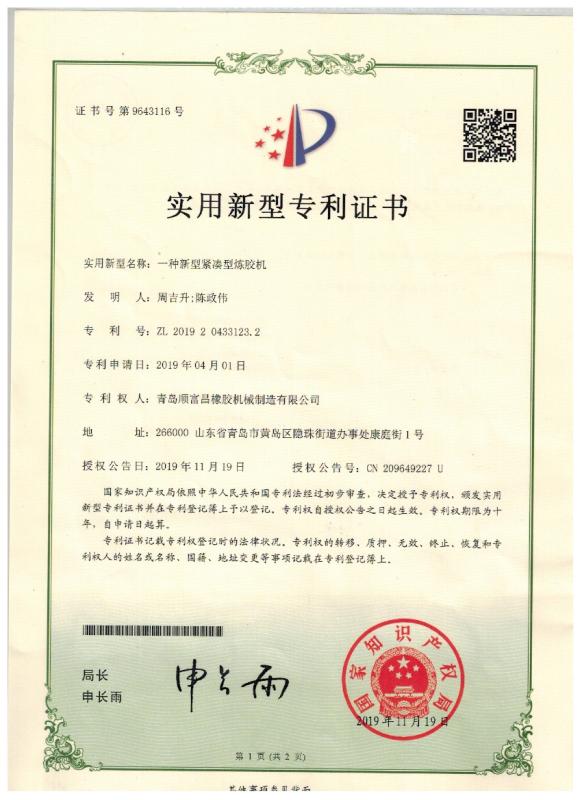

Certification

See All

Copyright 2023 ucbis.com All Rights Reserved.

Copyright 2023 ucbis.com All Rights Reserved.

75L Rubber Kneader Machine

75L Hard Chrome Coated Hard Tooth Reducer Rubber Kneader Machine

Technical Parameters:

| Item | X(S)N-3L | X(S)N-5L | X(S)N-10L | X(S)N-20L | X(S)N-25L | X(S)N-35L | X(S)N-55L | X(S)N-75L | X(S)N-110L | X(S)N-150L | X(S)N-200L |

| Total Volume of Mixing Chamber (L) | 8 | 15 | 25 | 45 | 55 | 75 | 125 | 170 | 250 | 325 | 440 |

| Working Volume of Mixing Chamber (L) | 3 | 5 | 10 | 20 | 25 | 35 | 55 | 75 | 110 | 150 | 200 |

| Driving Motor Power (KW) | 5.5 | 11 | 22 | 37 | 37 | 55 | 75 | 110 | 185 | 220 | 280 |

| Tilting Motor Power (KW) | 0.55 | 1.1 | 1.1 | 1.5 | 1.5 | 2.2 | 3 | 4 | 5.5 | 11 | 11 |

| Tilting Angle (°) | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 140 | 135 | 135 |

| Rotational Speed of the Rotor (Front/Rear) (RPM) | 32/24.5 | 32/23.5 | 32/25 | 32/27 | 32/27 | 30/24.5 | 30/24.5 | 30/24.5 | 30/24.5 | 30/24.5 | 30/24.5 |

| Pressure of Compressed Air (MPa) | 0.5~0.8 | 0.6~0.8 | 0.5~0.8 | 0.6~0.8 | 0.6~0.8 | 0.5~0.8 | 0.6~0.8 | 0.6~0.8 | 0.6~0.8 | 0.6~0.8 | 0.6~0.8 |

| Capacity of Compressed Air (m³/min) | ≥0.3 | ≥0.5 | ≥0.5 | ≥0.7 | ≥0.7 | ≥0.9 | ≥1.0 | ≥1.0 | ≥1.5 | ≥2.0 | ≥4.0 |

| Pressure of Cooling Water (Rubber Mixing) (MPa) | 0.2~0.4 | 0.2~0.4 | 0.2~0.4 | 0.2~0.4 | 0.2~0.4 | 0.3~0.4 | 0.3~0.4 | 0.3~0.4 | 0.3~0.4 | 0.3~0.4 | 0.3~0.4 |

| Pressure of Heating Steam (Plastic Mixing)(MPa) | 0.5~0.8 | 0.5~0.8 | 0.5~0.8 | 0.5~0.8 | 0.5~0.8 | 0.5~0.8 | 0.5~0.8 | 0.5~0.8 | 0.5~0.8 | 0.5~0.8 | 0.5~0.8 |

This Rubber Kneader is mainly used for plasticizing and mixing of natural rubber, synthetic rubber, reclaimed rubber and plastics, foaming plastics, and used in mixing of various the degree materials.

1. With completely condition, materials are mixed or plasticizing under certain pressure, controllable temperature, which makes high production efficiency and obtains excellent quality

2. Spiral angle and over lapping length of blades of the rotors are of reasonable design and make the materials to be dispersed uniformly

3. Rubber kneader machine surface where is contacted with the materials are all plated with hard chromium and polished, which is corrosion-resistant and wear-resistant

4. Jacket construction is adopted in rubber kneader machine parts that surfaces contact with materials to achieve excellent water-cooling or steam heating effect and fit in with the needs of plastics and rubber processing technology.

Our Services

1. Our engineers can design target machines for customers and send them the drawing to confirm. We are always on the side of saving your cost.

2. In the process of production, we will take photos and send to customers for their track the progress.

3. Documents such as packing list, commercial invoice, and bill of lading etc. will be sent after the delivery.

4. We could supply free English foundation DWG, installation drawing, user guide, maintenance manual and part drawing.

5. We supply overseas engineer service and help to train your workers to operate the machine.

Packaging & Shipping

Equipment painting completed before delivery, and then wrapped with stretch film, avoid rubbing the paint off the surface, wooden packaging can be customized, key parts, such as electronic control box, will be wrapped by shockproof packaging materials, and then packed in wooden cases.

Visit Website